Image: Luis Zuniga, Alfex CNC Australia

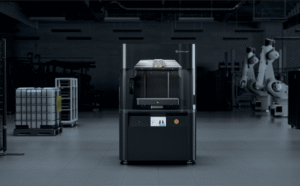

Alfex—and Markforged printers—are critical players in reshoring, supply chain resilience, and precision fabrication for SMEs and defence. It’s about industrial impact, not toys or prototypes.

This week as part of our INNOVATIONS INTERVIEWS- we catch up with Luis Zuniga, Sales Manager for Additive Manufacturing – a team member of the very active Alfex CNC Australia.

“Luis, 3D printing has moved far beyond prototyping. How are Markforged metal and composite printers being used in real, end-use Australian manufacturing today?”

Luis Zuniga: Australian manufacturing has been in declining since the closure of the large automotive manufacturing sector. We now rely heavily on imports, both for finished goods and for spare and replacement parts. Our idea is to empower Australian business, allow them to produce their own components, in metal and composite materials, and thus reducing the time its takes to get parts made, as well as controlling the cost to make them.

“What sectors in Australia are currently embracing metal additive manufacturing—mining, defence, aerospace?”

Luis Zuniga: Australian industry is well varied and diverse, there are many different sectors taking advantage of Additive Manufacturing. Food & Beverage, Meat production, Automotive – racing teams, Defence, Aerospace, Medical, just to list a few.

“Supply chain disruptions have hit local manufacturers hard. Can in-house 3D printing with Markforged tech help reduce downtime and dependency on imports?”

Luis Zuniga: There are two main catalyst to mention, when talking about import dependency. The COVID-19 pandemic was a major wake-up call for all companies importing their goods from overseas, especially from China. The other was the blocking of the Suez canal in 2021. This disrupted an already fragile industry, and exacerbated the dependency of our major sectors on imports. It makes total sense to take control of where your parts come from, when and for how much.

“Why should a mid-sized Australian workshop consider investing in a Markforged printer over traditional CNC or overseas fabrication?”

Luis Zuniga: Australia is a big country, we have lots of urban centres scattered throughout the country and in many ways this allows for a decentralisation of our manufacturing. At the same time this places a huge burden transporting components, from one end of the country to another, or from overseas markets to regional centres, or small towns. We have found having the ability to implement a decentralised method of manufacturing allows for a far more diversified manufacturing experience. Additive Manufacturing allows companies to manufacture very complex components without the need to machine anything. Markforged machines provide Australian manufacturing with the opportunity to produce components with the strength of Aluminium, without the need for any other type of machine. This Additive Manufacturing process empowers manufacturers and removes the need for traditional methods, or importing large quantities of Overseas made parts.

At the same time, established players have access to new technology which can work hand in hand with their traditional manufacturing methods. Offering these services is another way of taking advantage of Additive Manufacturing, and of the Markforged machines.

“Carbon fibre and metal composite printing sounds expensive. How close are we to true affordability and accessibility for everyday manufacturing teams?”

Luis Zuniga: Alfex is a company well known as being a supplier of quality manufacturing equipment, in all aspects of the word and for every industry. Our customers come from every walk of life, SMEs, multi nationals, from many different fields.

One of the main drivers for a company to invest in new technology is how much time and money they can save by accessing Additive Manufacturing – and this is happening now. Carbon Fibre and Metal printing sound expensive, complicated, sophisticated. These are just outdated ideas about the technology. You print what you need, there can be little to no waste if the parts are designed to suit this process. This applies to both composite and metal printing. Design to suit the end-use part.

Time is a factor seldom mentioned when talking about Additive Manufacturing. The Markforged ecosystem allows for a hands-off operational model, where the machines do the work whilst your time is well used in other aspects of the business. Having a machine running unattended for 24 hours means you will have an operator free to perform any other tasks for 3 working days.

“We often hear about flashy design use-cases for 3D printing—but what’s the most boring but brilliantly effective thing someone’s made using a Markforged printer?”

Luis Zuniga: This is very true, we hear about the space-going satellite parts, the sport cars with their weight saving designs, the drone bodies with reduced drag coefficients, medical and research purposes.

The everyday, almost certainly unheralded end-use parts are the unattractive examples that get very little press. These parts make up the vast majority of the Markforged printer’s work load, and they do this brilliantly. One such example is a simple Tannery Gear produced by a meat processing plant in Australia. This gear was printed as a prototype, replacing a well worn metal gear. There are many components used in automation systems, which do not get much attention but provide huge costs savings, when compared to injection moulded or machines components. Other small components, such as bolts, rollers, spacers, etc also get printed quite regularly and increase the versatility of the technology.

“Does Australia have the skilled labour needed to scale additive manufacturing—or is there still a big training gap?”

Luis Zuniga: Australia’s constant push for innovation and demonstrated ability to create new and exciting products places gives us an edge when it comes to skills. This edge however does mean we tend to have a shortage of skilled labour to run new technologies. At Alfex CNC Australia, we are driven to keep up to date on industry trends and ongoing training for all team members.

For more information contact Luis Zuniga, Sales Manager for Additive Manufacturing at Alfex CNC Australia.