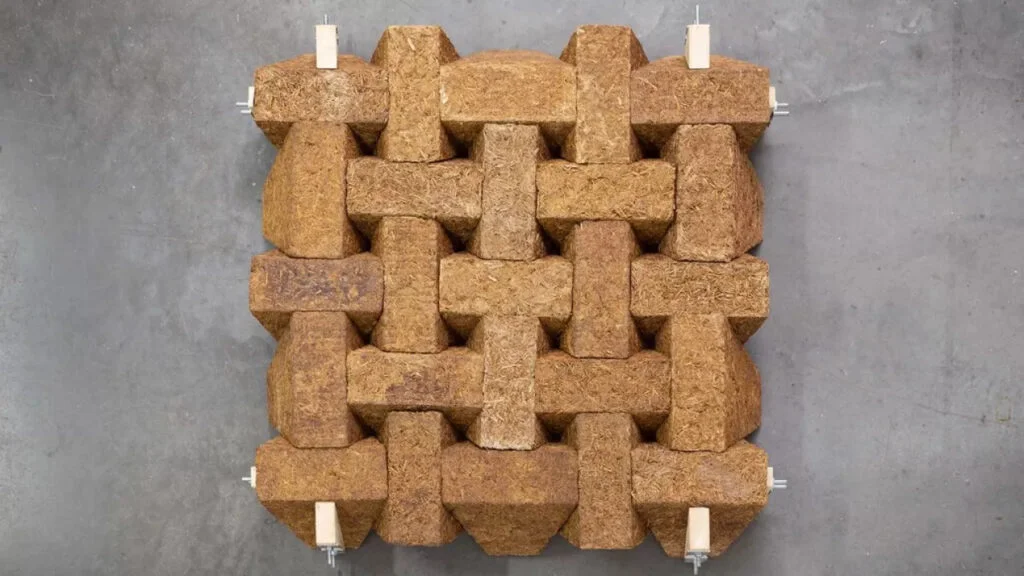

Sugarcrete® Brick Redefines the Sweet-Spot Alternative to Concrete

The Sugarcrete™ project, born from a collaboration between the University of East London (UEL) , Grimshaw Design Technology Group, and Tate & Lyle Sugars, is a new innovative low-carbon biomaterial building brick made out of bagasse, a dry pulpy fibrous bi-product material of sugarcane. Exploring innovations to convert waste – sugar cane is one of the largest global crops – into a useful construction material is essential in reducing waste, and carbon and developing a regenerative circular economy.

It was shortlisted in the ‘Build a Waste-Free World’ category for the 2023 Earthshot Prize – an initiative launched by Prince William in 2020 to search for and scale the most innovative solutions from people and organisations worldwide to address the world’s greatest environmental challenges.

Global Architecture studio Grimshaw’s interest in interlocking geometries has brought new opportunities to deploy Sugarcrete®️ .

Grimshaw explains that it is a spanning element composite floor slab, that can be constructed, demounted, and reused, and is fire-resistant – called Sugarcrete®️ Slab. This is one of a series of prototypes in developing innovative construction applications, which can be applied, disassembled, or extended in new or existing structures.

Grimshaw has offices in Australia- Melbourne, Sydney, New Zealand-Auckland, Dubai, London, Paris, New York, Los Angeles and New York. A roll-out of Sugarcrete®️ Slab from Grimshaw’s urban global office locations would be outstanding – to ‘Build a Waste-Free World’ – but equally, it would be exceptional, to establish community industries in Asia and the Pacific where the sugar cane is abundantly grown, insitu, creating a new Green Economy for the locals with great export potential. (Another Grimshaw architectural project worth mentioning is The Eden Project, UK, working with nature to respond to the planetary emergency.)

Image credit: Chris Hopkinson

The Sugarcane biomaterial can be used as a brick, an insulating panel, or a load-bearing element. Developed to be an environmentally friendly and affordable alternative to traditional bricks and concrete, Sugarcane is also remarkable in its efficiency in converting CO2 to biomass—up to 50 times more than forestry.

“Despite the global aim to hold global warming to 1.5 degrees Celsius [2.7 degrees Fahrenheit], it is estimated that our global built floor areas will double by 2060. Therefore, we must develop alternatives to current construction methods,” UEL senior lecturer Armor Gutierrez Rivas told Construction Management.

Being a significant crop grown in Asia, Sugarcrete has enormous Green Economic potential for communities by increasing domestic economies and export markets as matched in the UN SGD’s of reducing poverty and increasing durable housing and livelihoods. The world’s largest crop by production volume, is Sugarcane, with almost two billion tonnes produced yearly worldwide. Of this, 600 million tonnes of ‘bagasse’ are produced- a fibrous substance that’s left behind after the juice of the sugarcane plant is harvested. For every 10 tonnes of Sugarcane crushed, 3 tonnes of wet bagasse is produced.

“The next steps of the research will see the development and co-design of digital tools linked to by-product availability from diverse crops and regions and performance criteria that map the potential to deploy Sugarcrete globally,” the Sugarcrete team told Dezeen.

Get in touch with Sugarcrete® team and with Grimshaw Design Technology Group

Editor’s Note”: Energy and Construction are the biggest contributors of Carbon Emissions and both are competing for bagasse supplies, with sugarcane being diverted to biofuels/ethanol production. Another consideration is ‘Water’. The water footprint of Sugarcane is 210 liters of water to produce 1kg of sugarcane of which 15% is the bi-product, Bagasse.